Additive manufacturing of magnetic materials - AddMag

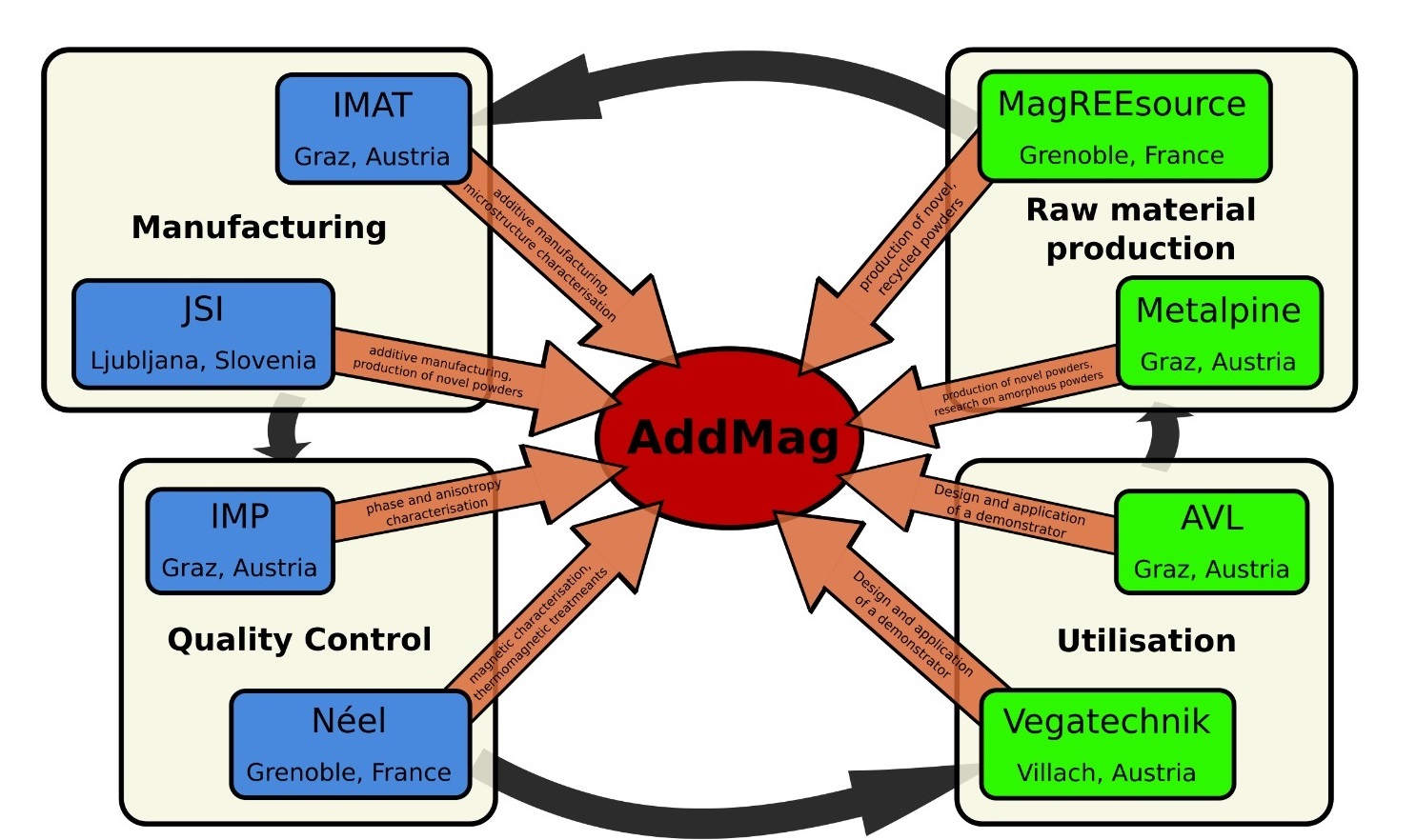

The AddMag project has successfully demonstrated that additive manufacturing (AM) can produce permanent magnets with exceptional magnetic performance, dimensional accuracy, and sustainability. At the heart of the project was the ambition to replace conventional, inflexible manufacturing processes with AM, which enables near-net-shape production and reduces reliance on virgin rare earth materials. The powder production team lead by the French company MagREEsource achieved a major breakthrough by developing a closed-loop recycling process for Nd-Fe-B magnets, producing powder with ultra-low oxygen and hydrogen content (≤95 ppm O₂, < 5 ppm H) while preserving over 93% of the material's remanence.Here, AddMag delivered tangible industrial progress: MagREEsource scaled up its hydrogen-based recycling technology, positioning itself as a future supplier of high-quality recycled Nd-Fe-B powder, while Metalpine advanced its powder spheroidization process, enabling an up-cycling of recycled and non-spherical powders in AM. This innovations not only minimize the environmental impact of magentic materials but also support Europe's strategic goal of reducing dependency on primary rare earth sources. For Fe-Cr-Co alloys, AddMag pioneered in-situ alloying and anisotropic printing, resulting in components with tailored microstructures and strong magnetic properties (e.g., remanence ~1.0 T). While the Fe-Cr-Co pathway fully met its targets, the Nd-Fe-B route—though technologically promising—highlighted the need for further R&D to achieve scalability for larger components. The project's scientific rigor is reflected in two peer-reviewed publications and two additional papers are currently under review. The scientific advances made in AM magnet production were validated through three industrial Use Cases: a bistable magnetic valve (AVL) that operates with zero energy in steady state, a high-precision magnetic sensor for hydrogen flow measurement, and an electro-permanent lifting system (Vega Technik) designed to replace energy-intensive legacy technologies. A key outcome was the proof-of-concept for energy-saving magnetic devices, such as AVL's bistable valve and levitation-based sensor, which minimize operational energy use and improve system efficiency. These innovations align with broader sustainability goals by reducing material waste, cutting CO₂ emissions, and supporting the circular economy. While the project achieved most of its objectives, it also identified critical challenges—particularly in scaling up the AM process for Nd-Fe-B magnets—which will guide future research. The consortium's findings have already sparked follow-up initiatives, including patent applications and plans to advance demonstrators to higher Technology Readiness Levels (TRL 5–6). Overall, AddMag has shown that additive manufacturing can revolutionize magnet production, making it more sustainable, flexible, and efficient.

- Arneitz, S., Buzolin, R., Rivoirard, S. & Sommitsch, C. Additive manufacturing of an Fe–Cr–Co permanent magnet alloy with a novel approach of in-situ alloying. Eur. J. Mater. 2, 475–497 (2022).

- Mairhofer, T., Arneitz, S., Hofer, F., Sommitsch, C. & Kothleitner, G. Micro- and nanostructure of additively manufactured, insitu alloyed, magnetic spinodal Fe54Cr31Co15. J. Mater. Sci. 58, 7119–7135 (2023).

- Additive Manufacturing of Fe-Cr-Co magnet structures with a functionally graded chemical composition; under review

- Influence of key printing parameter on the development of microstructure and texture in Fe-Cr-Co and its effects on the magnetic properties; under review; pre- print: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5377273