Ultra-Low Temperature Co-fired Ceramics for 6th Generation Electronic Packaging - ULTCC6G_EPac

The ULTCC6G_Epac project has achieved groundbreaking advancements in the development and validation of Ultra-Low Temperature Co-fired Ceramic (ULTCC) materials, paving the way for next-generation microwave and millimeter-wave applications.

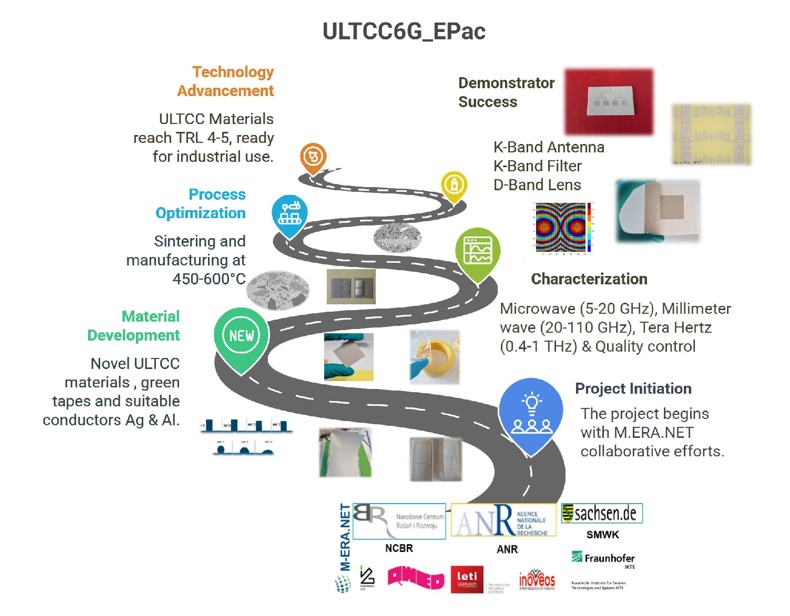

Through a collaborative effort involving leading research institutions and industry partners, the project has successfully progressed ULTCC materials to Technology Readiness Level 4-5, demonstrating their potential in real-world scenarios.

Material Innovation: The project successfully developed novel ULTCC materials, including SAG728, ZSG424, and ZSG8470, each with tailored properties for high-frequency applications. Comprehensive characterization of these materials,focusingonstructural,microstructural,andmicrowavedielectricproperties,providedasolidfoundationfortheirapplication. Consistent and stable tape casting processes were established, enabling batch production and supporting the MLC process value chain.

Process Optimization: Sintering conditions were optimized to achieve the best possible microwave dielectric properties, crucial for high-frequency performance. Optimized processing parameters for MLC fabrication were developed, ensuring reliable and repeatable manufacturing. Compatible conductor co-firing and post-firing strategies were implemented, facilitating seamless integration with conductive elements.

Demonstrator Success: Three demonstrators showcased the capabilities of the developed materials and processes:K-band LTCC and ULTCC antennas, demonstrating high-precision manufacturing and performance. A K-band ULTCC filter, proving the feasibility of ULTCC materials in passive componentapplications. AD-bandTAarraylensantenna,pushingtheboundariesofmillimeter-wavetechnology.LTCCtechnologywasprovento be very effective for high precision millimeter wave antenna production.

Technology Advancement: The project successfully advanced ULTCC materials to TRL 4-5, demonstrating their readiness for industrial applications. The development of a foundational tape casting strategy and optimized processing parameters lays the groundwork for future commercialization. The project has provided a new level of THz characterization data.

Collaboration and Knowledge Transfer: The project fostered strong collaboration between research institutions and industry partners, facilitating knowledge transfer and accelerating innovation. The dissemination of project results through publications, conferences, and open access repositories ensures that the advancements benefit the wider scientific and industrial community.

Looking Ahead: The ULTCC6G_Epac projecthas madesignificantstrides inadvancing ULTCCtechnology. Whileachieving ultra-low dielectric loss remains anongoing researchfocus, the project's achievements have demonstrated the immense potential of these materials for revolutionizing high-frequency applications. The project's success underscores the importance of collaborative research and development in driving technological innovation and strengthening European competitiveness in the global marketplace.