Materials for circular economy – industrial waste based geopolymers composites with hybrid reinforcement - GEOSUMAT

The main objective of the project “Materials for circular economy ‐ industrial waste based geopolymers composites with hybrid reinforcement” was to design & characterise new eco‐friendly geopolymers (GPs) composites based on industrial and mining wastes, ideal for contribution to a circular economy.

Properties of more than 21 local waste streams from Norway, Czech Republic, Iceland Poland and Romania were characterized by particle size distribution, mineralogy, chemical composition or SEM images. Materials suitability for geopolymer production were categorised into 3 categories: precursor (17 materials), aggregates (11 fine and 4 coarse), and activator (1), with potential for further mechanical (11 materials) or thermal (7 materials) activation. Precursors such as diatomite dust, wood waste ash, geothermal waste, aluminium waste, refused derived fuels, waste brick powder or waste calcined clay (RON D450) were investigated. More than 22 mix designs, containing selected industrial and mining wastes present in developed database, were prepared and tested by all project partners. LCA analyses conducted by CTU, PK, and GEROSION verified the reduction of landfilled waste by approximately 20 %.

Furthermore, hybrid reinforcement and particle additives for improvement of GP mechanical and functional properties were conducted using a minimum 7 types of fibers such as waste fiberglass reinforcement fabric, natural fibers , AR glass minibars and basalt Minibars from ReforceTech, waste from recycling of photovoltaic, and 3 waste particle additives, such as recycled concrete aggregates, recycled geopolymer aggregates and waste from photovoltaic recycling. Designed GPs composites are dedicated for civil engineering applications such as precast elements, as results showed advantageous properties by curing in elevated temperatures (50 °C) and fast hardening (open time even down to 1 minute and 60% of final strength in 12 hours). Durability testing (freeze-thaw with deicing salt, chloride ingress or wear resistance) then suggests suitable utilisation in marine ambient (tested at Icelandic and Norwegian harbour by Gerosion and UiT), and industrial floors as they can withstand high loads and chemical attack (tested in Czech Republic by CTU and Chemstr). Additionally, self-heating or antimicrobial properties of waste-based GP were successfully tested. Furthermore, carbon dioxide reduction was involved in 3 stages of GP development: (i) use of waste materials, (ii) carbon dioxide enrichment/storage/in activating solution during GP production, and (iii) final material sequestration of atmospheric carbon dioxide. Finally, life cycle analyses with emphases on carbon footprint and resource preservation, and economic viability calculations supported practical laboratory testing.

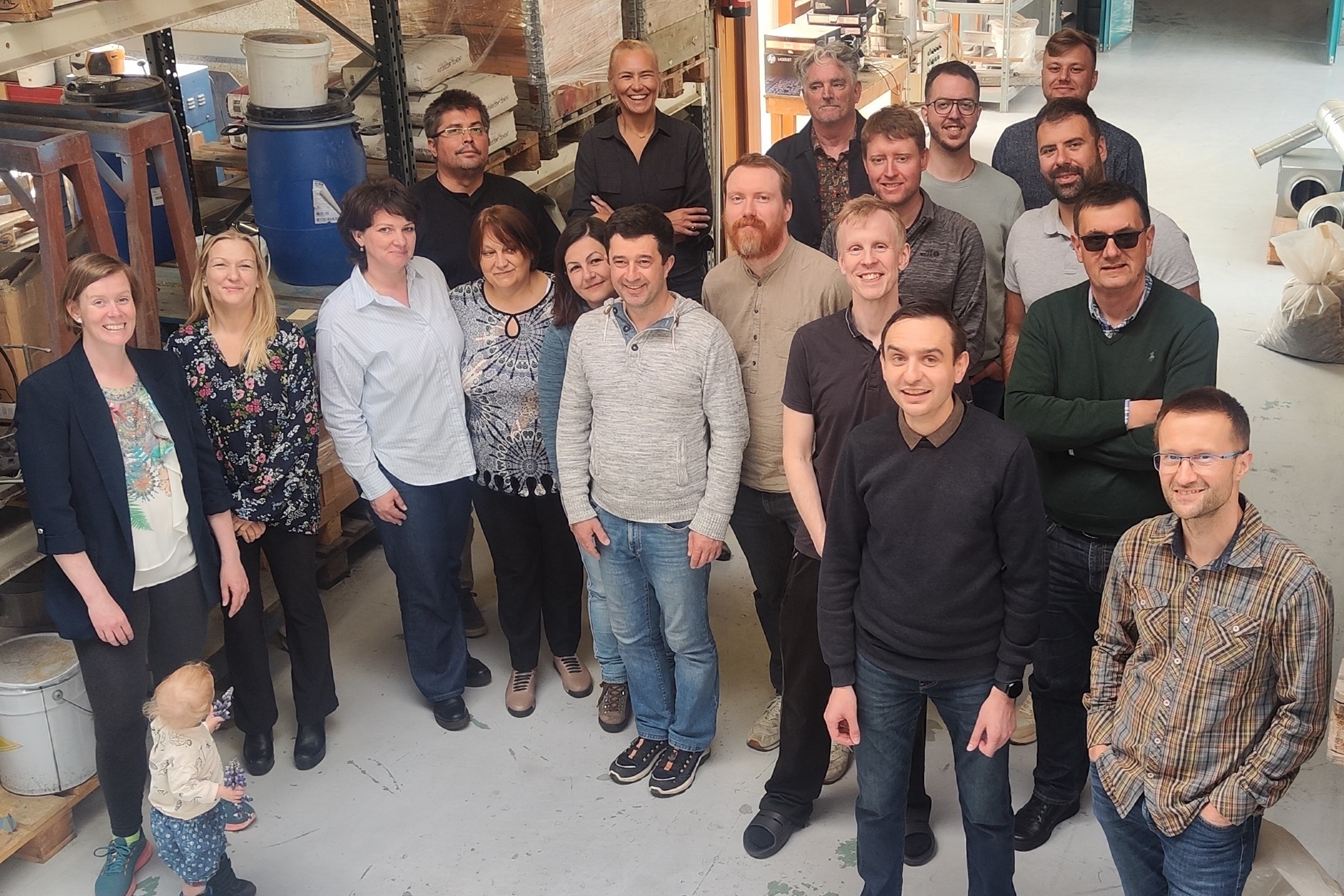

The project strongly contributed to the development of science as well as practical (industrial) applications, thanks to 16 scientific articles, 18 conference oral or poster presentations, and 3 demonstration sites. The project created an exceptional environment for knowledge sharing among project partners, the scientific community, industry, and education through international cooperation between Norway, Iceland, Poland, Romania, and the Czech Republic. The indicator for successful cooperation is 5 in-person partner meetings in 5 different locations, organizing 2 online seminars, 1 conference, 3 discussions with policymakers, 2 submitted project applications, one pending patent, one pending functional sample demonstrating reached TRL 6 and a number of visits to local industries to collect input waste materials and discuss the use of newly developed GP.

Throughout the GEOSUMAT project, 53 researchers, of whom 19 were females, 23 were young researchers, contributed to the development of new GP materials for industrial applications. In conclusion, the GEOSUMAT project has successfully proved the potential of using local waste materials sustainable and high-performance geopolymers. Through international collaboration and research, the project has achieved significant advancements in reducing carbon emissions and developing eco-friendly construction materials.