13.10.2025

New Success Story: AddMag

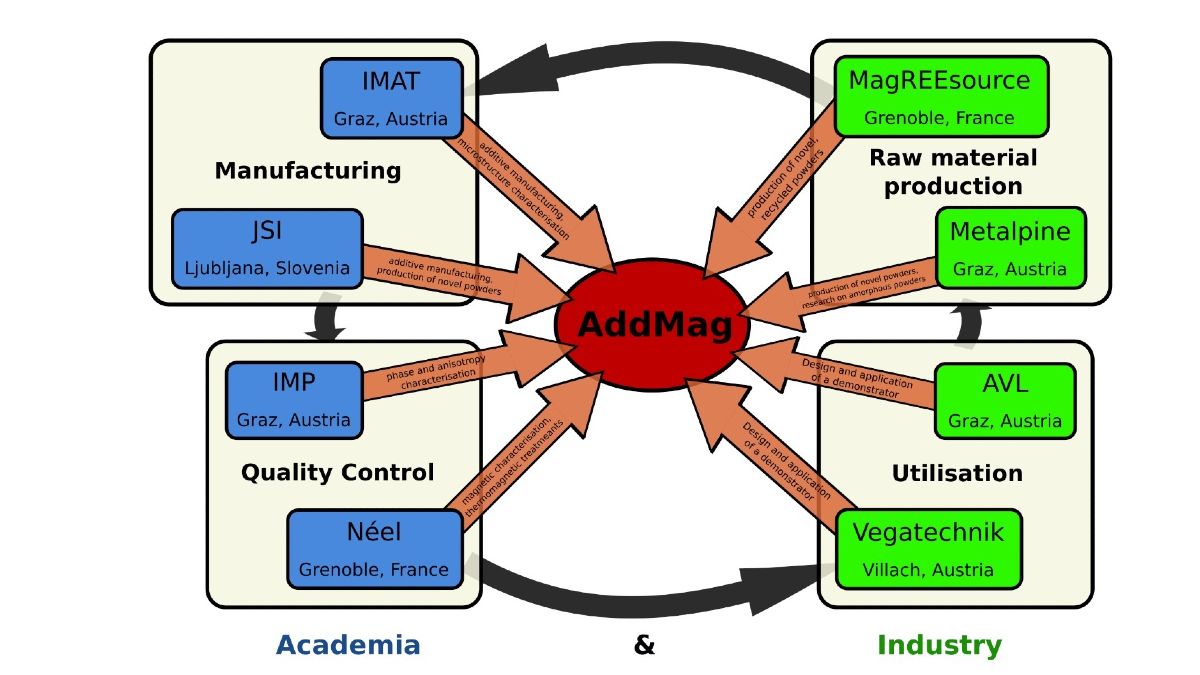

The AddMag project has successfully demonstrated that additive manufacturing (AM) can produce permanent magnets with exceptional magnetic performance, dimensional accuracy, and sustainability.

At the heart of the project was the ambition to replace conventional, inflexible manufacturing processes with AM, which enables near-net-shape production and reduces reliance on virgin rare earth materials. The powder production team lead by the French company MagREEsource achieved a major breakthrough by developing a closed-loop recycling process for Nd-Fe-B magnets, producing powder with ultra-low oxygen and hydrogen content (≤95 ppm O₂, < 5 ppm H) while preserving over 93% of the material's remanence. Here, AddMag delivered tangible industrial progress: MagREEsource scaled up its hydrogen-based recycling technology, positioning itself as a future supplier of high-quality recycled Nd-Fe-B powder, while Metalpine advanced its powder spheroidization process, enabling an up-cycling of recycled and non-spherical powders in AM.

Read more about the success stories of projects funded within the M-ERA.NET Calls: here