Graded interphases for enhanced dielectric and mechanical strength of fiber reinforced composites - GRADIENT

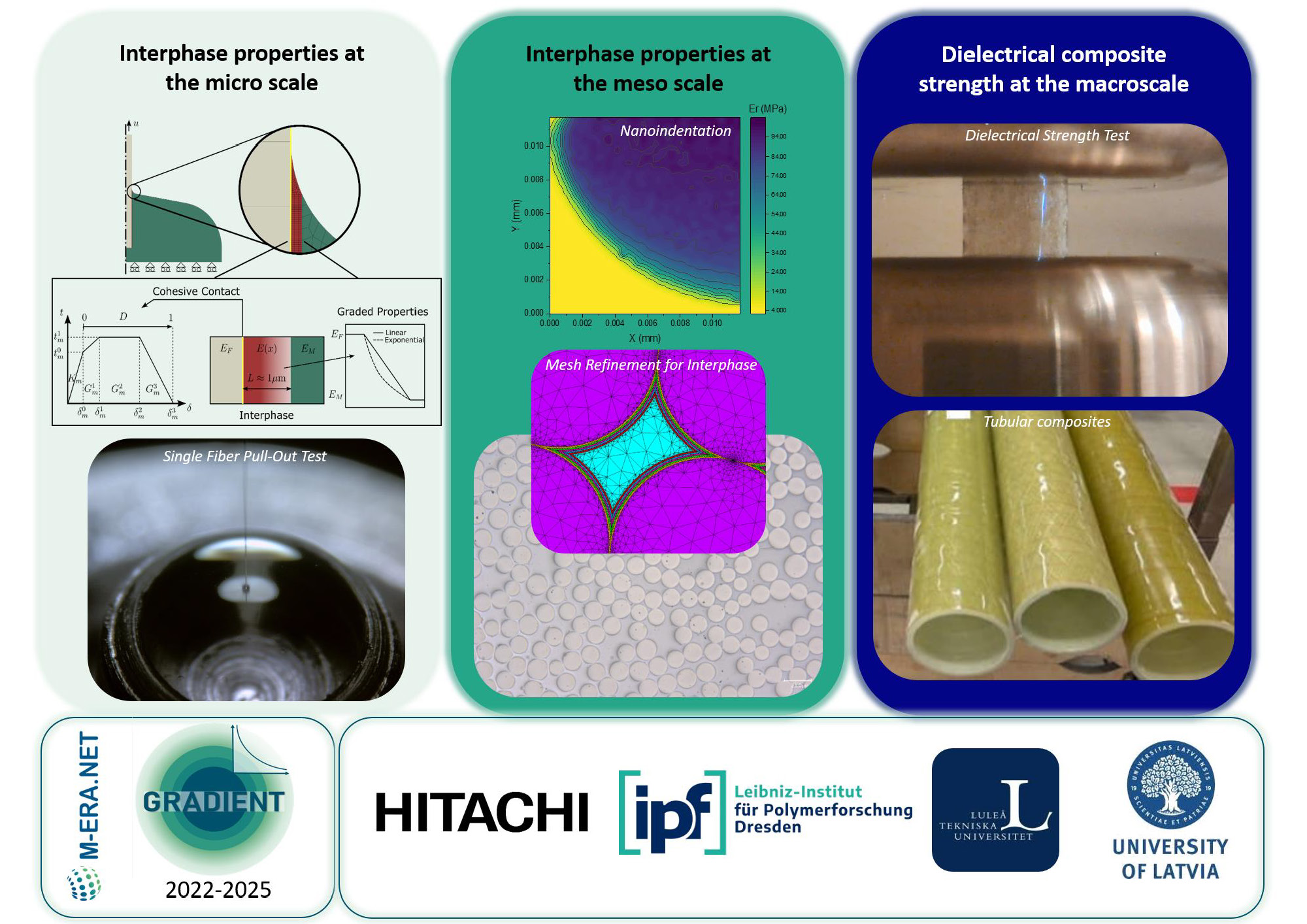

Power transformers and switchgears are key components made of high-performance composites used in power grids. Their availability and robustness have a decisive influence on the reliability and profitability, especially for the future expansion of power grids. Composites mechanical and dielectric strength is strongly influenced by the fiber-matrix interphase, the main source of micro-scale damage. The project’s objective was therefore to develop new methodologies and validation tools for interphase optimization, while also exploring approaches to reduce stress concentrations within the interphase to enhance the durability of composite structures. In this project, researchers developed and carried out experiments on several levels — from microscopic tests on single fibers to larger tests on composite plates and tubes. Tailored glass fibers (GF) were produced via a pilot spinning line, where a new approach (nanoclay sizing) was tested to optimize the interphase. In the micro-scale, interfacial shear strength was measured by single fiber pull-out (SFPO) tests. The interphase stiffness and thickness was measured and visualised by nanoindentation. A new methodology using scanning electron microscopy with energy dispersive x-ray spectroscopy (SEM/EDX) led to a faster and more feasible approach for determining interphase thickness. All techniques confirmed the presence of a graded interphase, with gradual variations in properties and chemical composition. Finite element method (FEM) simulations of the SFPO, explicitly including a graded interphase, were carried out to understand the damage process of fiber-matrix debonding and to determine corresponding mechanical parameters. A generalized variant of a traction separation law was introduced, leading to the conclusion that fiber-matrix debonding is governed by plastic deformation. At meso-scale, electrical tests revealed that breakdowns often begin near the interphase, proving its importance not only for mechanical but also for electrical performance. Further modeling confirmed that including the interphase in calculations makes predictions of material strength and stiffness much more accurate. An interactive tool (Fiber.net) was developed to predict elastic transverse properties of unidirectional (UD) composites. Finally, large-scale tests on tubular composite structures showed that overall performance depends on many factors — not just the materials themselves but also how precisely they are manufactured. This underlines why studying materials at smaller scales is so valuable: it helps identify the best combinations of fibers, coatings, and resins before production, guiding better material selection and process optimization.

Dresden e.V. (IPF)

- Roetsch, K.;, Bittrich L.; Bercini Martins, A.; Scheffler,C.; Spickenheuer, A.; Stommel, M. Finite Element and Machine

Learning-Assisted Analysis of Fiber-Matrix Interphase in Single-Fiber Pull-Out Tests. Composites Part B: Engineering, Volume

305, 2025, 112702, ISSN 1359-8368. https://doi.org/10.1016/j.compositesb.2025.112702 - Twelve communication at scientific congresses, two scientific degrees and three workshops.