Multi-scale laser surface texturing for low ice-friction contacts - M-LUGE

Project summary

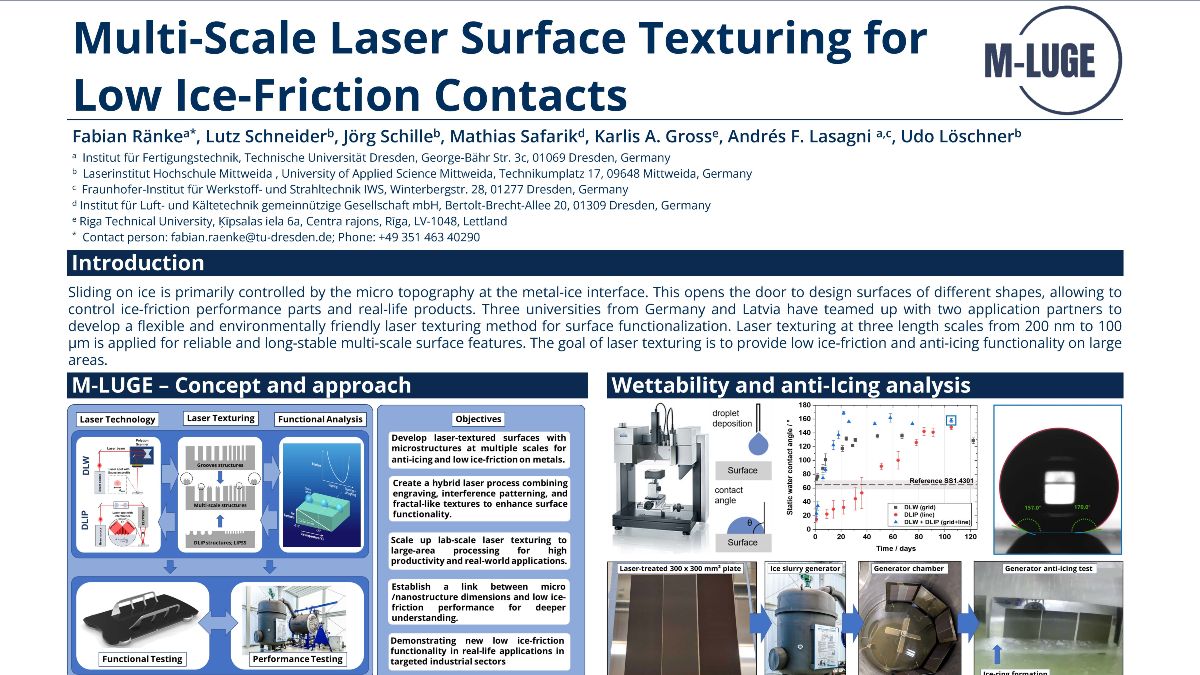

Sliding on ice is primarily controlled by the micro topography at the metal-ice interface. This opens the door to design surfaces of different shapes, allowing to control ice-friction performance of functional parts and real-life products. Three universities from Germany and Latvia have teamed up with two application partners to develop a flexible and environmentally friendly laser texturing method for surface functionalization. Laser texturing at three length scales from 200 nm to 100 μm is applied for reliable and long-stable multi-scale features. The goal of laser texturing is to provide low ice-friction and anti-icing functionality on large areas. This is demonstrated by the functional testing of laser textured skeleton runners and slurry-ice evaporators, supporting the European Green Deal by clean energy generation. The range of three laser texturing methods offers unmatched patterning capability and speed for hierarchical topography designs for innovations in surface engineering.Project Details

Call

Call 2021

Call Topic

Innovative surfaces, coatings and interfaces

Project start

01.08.2022

Project end

30.07.2025

Total project costs

840.020 €

Total project funding

840.020 €

TRL

2 - 5

Coordinator

Prof. Dr. Udo Loeschner

loeschne@hs-mittweida.de

Hochschule Mittweida, TECHNIKUMPLATZ 17, 09648 MITTWEIDA, Germany

Partners and Funders Details

| Consortium Partner | Country | Funder | |

|---|---|---|---|

| Hochschule Mittweida https://www.hs-mittweida.de |

University | Germany | DE-SMWK |

| Technische Universität Dresden https://www.tu-dresden.de |

University | Germany | DE-SMWK |

| Rigas Tehniska Universitate https://www.rtu.lv |

University | Latvia | LV-VIAA |

Keywords

advanced surfaces technologies, functionalised surfaces, laser microprocessing, sustainable energy usage, energy consumption reduction, Energy efficiency, Laser highrate processing